Flat Top Laser Beams: A Unique Solution for Precision Applications

Flat Top Laser Beams: A Unique Solution for Precision Applications

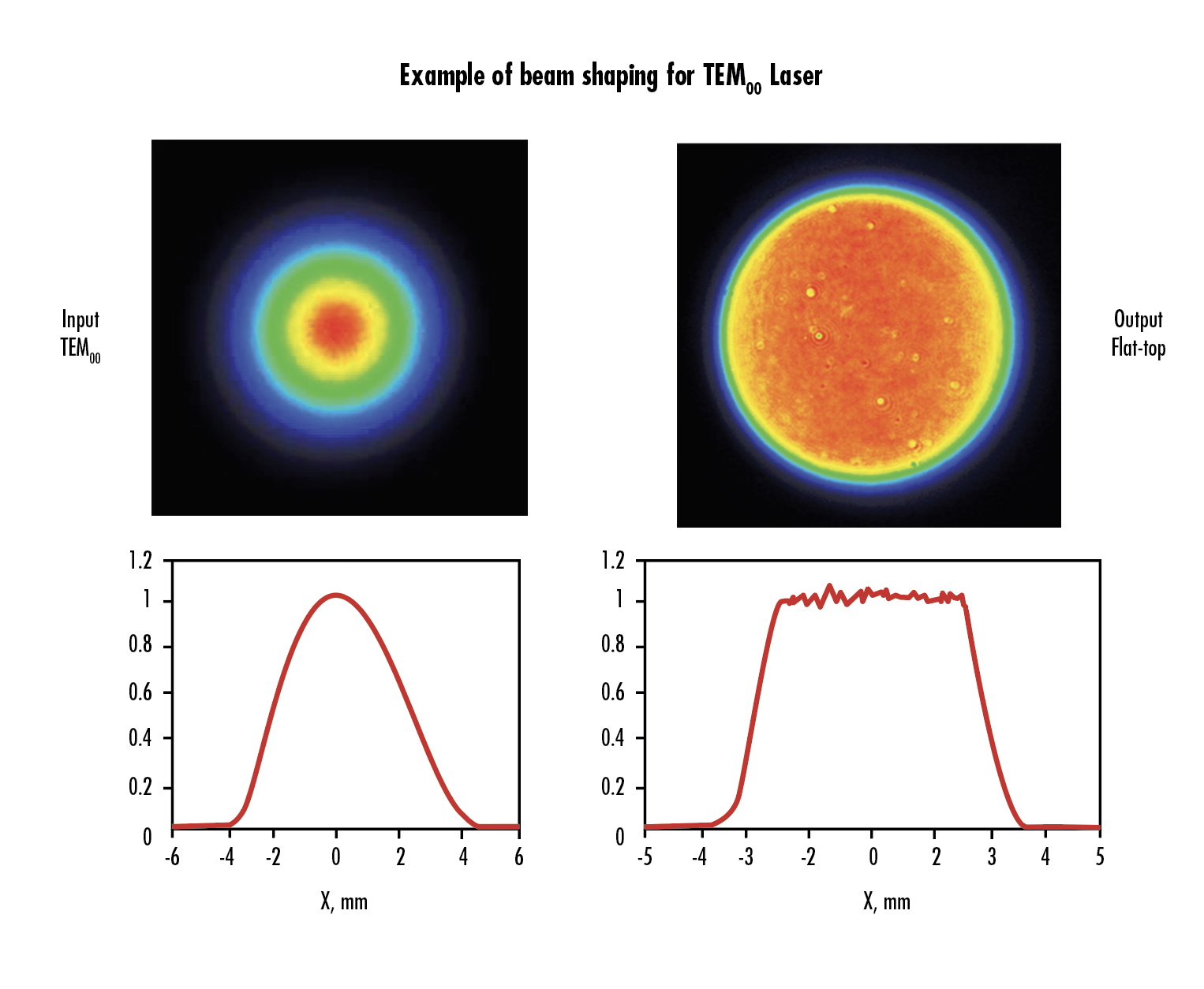

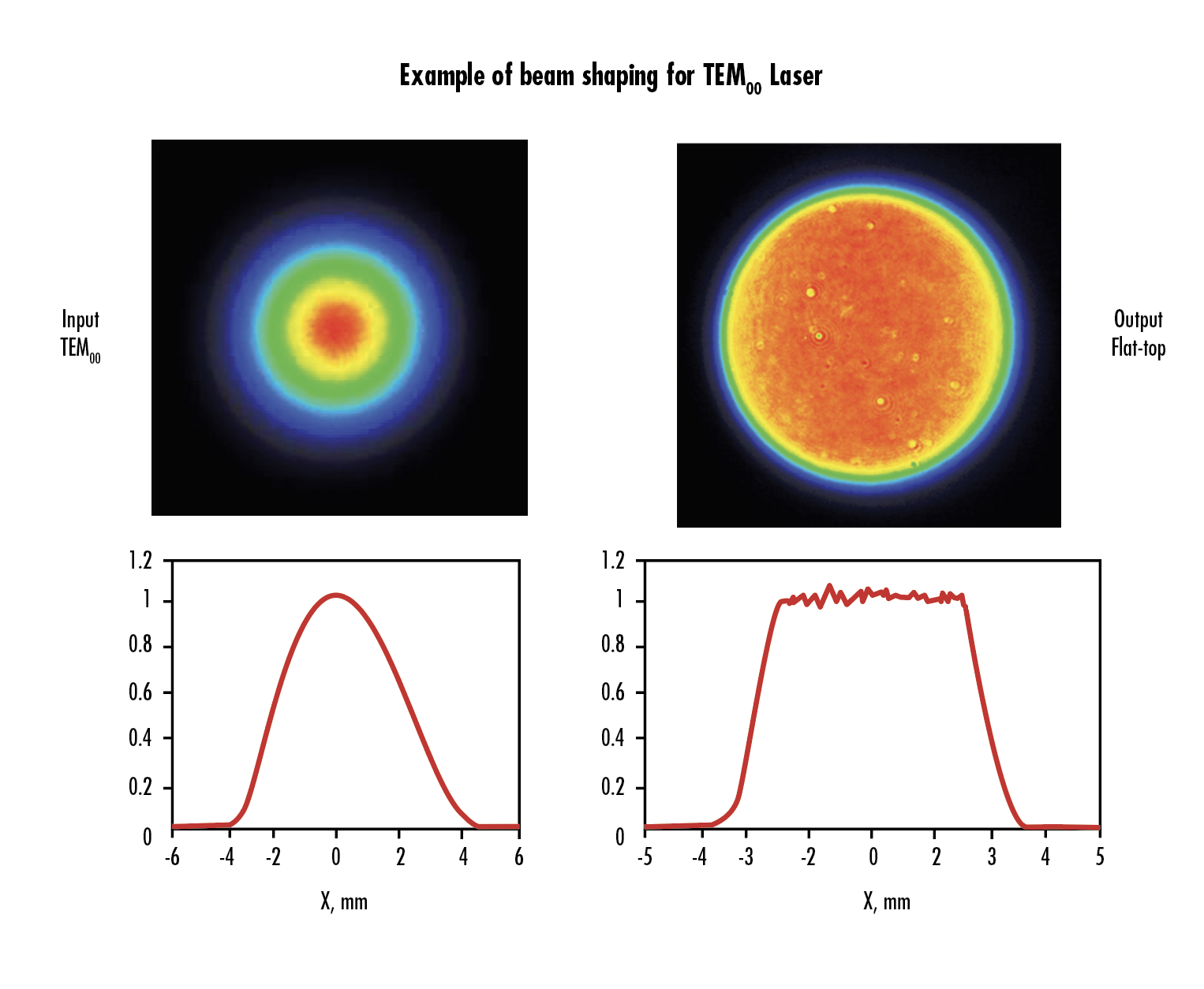

Laser beams have been used in various applications due to their unique properties, such as high intensity and directional coherence. Traditional Gaussian laser beams are widely used in many applications, but they have limitations in terms of their intensity distribution and beam shape, which can cause non-uniformity in the output. This is where the flat top laser beams come into play.

Flat top laser beams are characterized by their uniform intensity distribution across a certain area, which makes them ideal for applications that require precision and uniformity. These beams are obtained by reshaping the Gaussian beams using optical components such as diffractive optical elements and spatial light modulators.

One of the significant advantages that flat top laser beams offer is the ability to achieve uniform intensity distribution, which can be used in applications such as laser cutting, surface treatment, and micromachining. These applications require a high degree of precision, and any non-uniformity in the output can cause errors and inaccuracies.

Another advantage of flat top laser beams is their ability to have a rectangular shape, which is suitable for applications such as printing and scanning. The rectangular shape allows for greater coverage of the surface and more efficient use of the laser power.

The use of flat top laser beams is not limited to industrial applications; they are also becoming increasingly popular in biomedical applications such as photodynamic therapy and fluorescence microscopy. These applications require precise control of the laser power and intensity distribution, which can be achieved using flat top laser beams.

In conclusion, flat top laser beams are a unique solution for precision applications that require a high degree of uniformity and accuracy. They offer advantages over traditional Gaussian beams in terms of intensity distribution and beam shape. With their increasing popularity in various fields, we can expect to see more advancements and innovations in the use of flat top laser beams in the future.

Laser beams play a crucial role in numerous applications, from scientific research to industrial processes. In certain cases, a flat top intensity distribution is desired rather than the usual Gaussian-shaped beam. Achieving such a beam profile requires specific techniques that can modify the laser beam’s characteristics. In this article, we will explore various methods used to generate flat top laser beams and discuss their respective advantages and limitations.

One commonly employed technique for generating flat top laser beams is beam shaping using diffractive optical elements (DOEs). DOEs are specialized optical components that manipulate the phase or amplitude of light waves. By carefully designing the surface profile of a DOE, it is possible to diffract the incoming laser beam and reshape it into a desired intensity distribution, such as a flat top. This approach offers flexibility and enables the creation of customized beam profiles for specific applications.

Another technique involves the use of refractive optical systems. These systems utilize lenses and other optical components to shape the laser beam. By carefully arranging multiple lenses, it is possible to modify the beam’s intensity distribution and achieve a flat top profile. This approach is widely used in laser beam homogenization and can be adapted to different laser sources and wavelengths. However, it is important to note that refractive systems are limited by the diffraction properties of light, which can impose constraints on the achievable flatness of the beam.

Digital holography is a modern technique that has gained popularity in recent years for generating flat top laser beams. In digital holography, a hologram is created by interfering a reference beam with the beam under investigation. The hologram contains information about the wavefront of the beam, which can be numerically reconstructed to shape the beam into a flat top profile. Digital holography offers high precision and flexibility, allowing for real-time adjustments to the beam’s characteristics. However, it requires advanced computational resources and can be more complex to implement compared to other techniques.

Each of these methods has its own advantages and limitations, and the choice of technique depends on the specific requirements of the application. Factors such as the desired beam profile, beam size, power requirements, and available resources all play a role in selecting the most suitable approach. It is important to consider these factors carefully and consult with experts in the field to determine the optimal technique for achieving the desired flat top laser beam.

In conclusion, generating flat top laser beams involves the utilization of various techniques such as beam shaping with DOEs, refractive optical systems, and digital holography. These methods offer unique ways to modify the laser beam’s profile and achieve a flat top intensity distribution. Understanding the advantages and limitations of each technique is crucial for selecting the most appropriate method for a given application. By harnessing these techniques, researchers and engineers can tailor laser beams to meet the specific demands of their respective fields, unlocking new possibilities in science, industry, and technology.

Laser beams play a crucial role in numerous applications, from scientific research to industrial processes. In certain cases, a flat top intensity distribution is desired rather than the usual Gaussian-shaped beam. Achieving such a beam profile requires specific techniques that can modify the laser beam’s characteristics. In this article, we will explore various methods used to generate flat top laser beams and discuss their respective advantages and limitations.

One commonly employed technique for generating flat top laser beams is beam shaping using diffractive optical elements (DOEs). DOEs are specialized optical components that manipulate the phase or amplitude of light waves. By carefully designing the surface profile of a DOE, it is possible to diffract the incoming laser beam and reshape it into a desired intensity distribution, such as a flat top. This approach offers flexibility and enables the creation of customized beam profiles for specific applications.

Another technique involves the use of refractive optical systems. These systems utilize lenses and other optical components to shape the laser beam. By carefully arranging multiple lenses, it is possible to modify the beam’s intensity distribution and achieve a flat top profile. This approach is widely used in laser beam homogenization and can be adapted to different laser sources and wavelengths. However, it is important to note that refractive systems are limited by the diffraction properties of light, which can impose constraints on the achievable flatness of the beam.

Digital holography is a modern technique that has gained popularity in recent years for generating flat top laser beams. In digital holography, a hologram is created by interfering a reference beam with the beam under investigation. The hologram contains information about the wavefront of the beam, which can be numerically reconstructed to shape the beam into a flat top profile. Digital holography offers high precision and flexibility, allowing for real-time adjustments to the beam’s characteristics. However, it requires advanced computational resources and can be more complex to implement compared to other techniques.

Each of these methods has its own advantages and limitations, and the choice of technique depends on the specific requirements of the application. Factors such as the desired beam profile, beam size, power requirements, and available resources all play a role in selecting the most suitable approach. It is important to consider these factors carefully and consult with experts in the field to determine the optimal technique for achieving the desired flat top laser beam.

In conclusion, generating flat top laser beams involves the utilization of various techniques such as beam shaping with DOEs, refractive optical systems, and digital holography. These methods offer unique ways to modify the laser beam’s profile and achieve a flat top intensity distribution. Understanding the advantages and limitations of each technique is crucial for selecting the most appropriate method for a given application. By harnessing these techniques, researchers and engineers can tailor laser beams to meet the specific demands of their respective fields, unlocking new possibilities in science, industry, and technology.

Flat top laser beams have been gaining popularity in various fields due to their unique characteristics. These laser beams have a uniform intensity profile and controllable energy distribution, making them ideal for applications that require high precision and accuracy.

One field where flat top laser beams find utility is laser micromachining. This process involves using lasers to produce small features on a material surface. Flat top laser beams are used in this process as they can create precise and uniform cuts, thereby improving the quality of the end product.

Another application where flat top laser beams are useful is in lithography. Here, these beams are used to pattern a surface or create fine structures. Due to their uniform intensity profile, flat top laser beams can provide better control over the patterning process, resulting in higher resolution and accuracy.

Additive manufacturing is yet another field where flat top laser beams find extensive use. This process involves using lasers to selectively melt or fuse materials to create 3D objects. Flat top laser beams are ideal for this process as they can provide a uniform energy distribution, resulting in a more even and consistent melting process.

In laser annealing, flat top laser beams are used to heat up material surfaces to modify their properties. This process is used to improve the performance and durability of electronic devices. Flat top laser beams are preferred in this process as they can provide a more uniform heat distribution, resulting in better control over the annealing process.

Finally, flat top laser beams also have several medical applications. They can be used in procedures such as laser surgery and dermatology. The uniform intensity profile of these beams can help ensure that the energy is delivered precisely to the target area, minimizing damage to the surrounding tissue.

In conclusion, flat top laser beams have diverse applications in various fields such as laser micromachining, lithography, additive manufacturing, laser annealing, and medical procedures. Their unique properties such as the uniform intensity profile and controllable energy distribution make them ideal for applications that require high precision and accuracy. As technology continues to evolve, it is expected that flat top laser beams will find even more applications in the future.

Future prospects and advancements in the field of flat top laser beams are an exciting area of research that holds immense potential for various applications. As scientists and engineers continue to push the boundaries of laser technology, numerous advancements are being made to improve beam quality, increase power levels, and enhance the flexibility of generating flat top laser beams.

In recent years, researchers have focused on developing novel techniques to achieve higher beam quality in flat top lasers. One promising approach involves using diffractive optical elements (DOEs) and holographic techniques to shape the laser beam profile. These methods enable precise control over the intensity distribution, resulting in a more uniform and symmetric flat top beam. Ongoing research in this area aims to further optimize the shaping process, reduce losses, and expand the range of achievable beam shapes.

Advancements in laser technology have also led to significant progress in increasing the power levels of flat top laser beams. By employing innovative designs and utilizing high-power laser diodes, researchers have successfully scaled up the output power while maintaining beam quality. This has opened up opportunities for various applications that require high-power laser sources, such as material processing, laser cutting, and laser-induced breakdown spectroscopy.

Furthermore, the flexibility of generating flat top laser beams has improved with the development of new techniques. Adaptive optics systems, for instance, enable real-time correction of wavefront distortions, leading to better beam quality and shape control. This allows for dynamic beam shaping and adaptability to different target requirements, which is particularly beneficial in applications like laser materials processing, laser micromachining, and laser marking.

Looking ahead, flat top laser beams hold great potential for emerging fields such as quantum computing and advanced optical communication systems. In the realm of quantum computing, precise beam shaping and control are crucial for manipulating and addressing individual qubits. The uniform intensity distribution of flat top beams can help reduce errors and improve the overall performance of quantum systems. Similarly, in advanced optical communication systems, flat top beams can enhance the efficiency and reliability of data transmission, especially in high-speed and long-distance scenarios.

In conclusion, ongoing research and advancements in flat top laser beams are paving the way for exciting prospects in various fields. The development of new techniques and technologies promises to improve beam quality, increase power levels, and enhance flexibility. Moreover, the potential applications in emerging fields like quantum computing and advanced optical communication systems further highlight the significance of these advancements. As researchers continue to unravel the full potential of flat top laser beams, we can anticipate a future where these lasers play a vital role in shaping our technological landscape.