Flat Top Laser Beams: A New Dimension in Laser Technology

Flat Top Laser Beams: A New Dimension in Laser Technology

Laser technology has revolutionized numerous fields, from manufacturing to medical procedures, with its precision and versatility. Among the many types of laser beams, flat top laser beams have emerged as an innovative addition, redefining the way lasers are utilized in various applications. In this article, we will explore the significance of flat top laser beams and how they differ from the traditional Gaussian laser beams in terms of intensity distribution and beam shape.

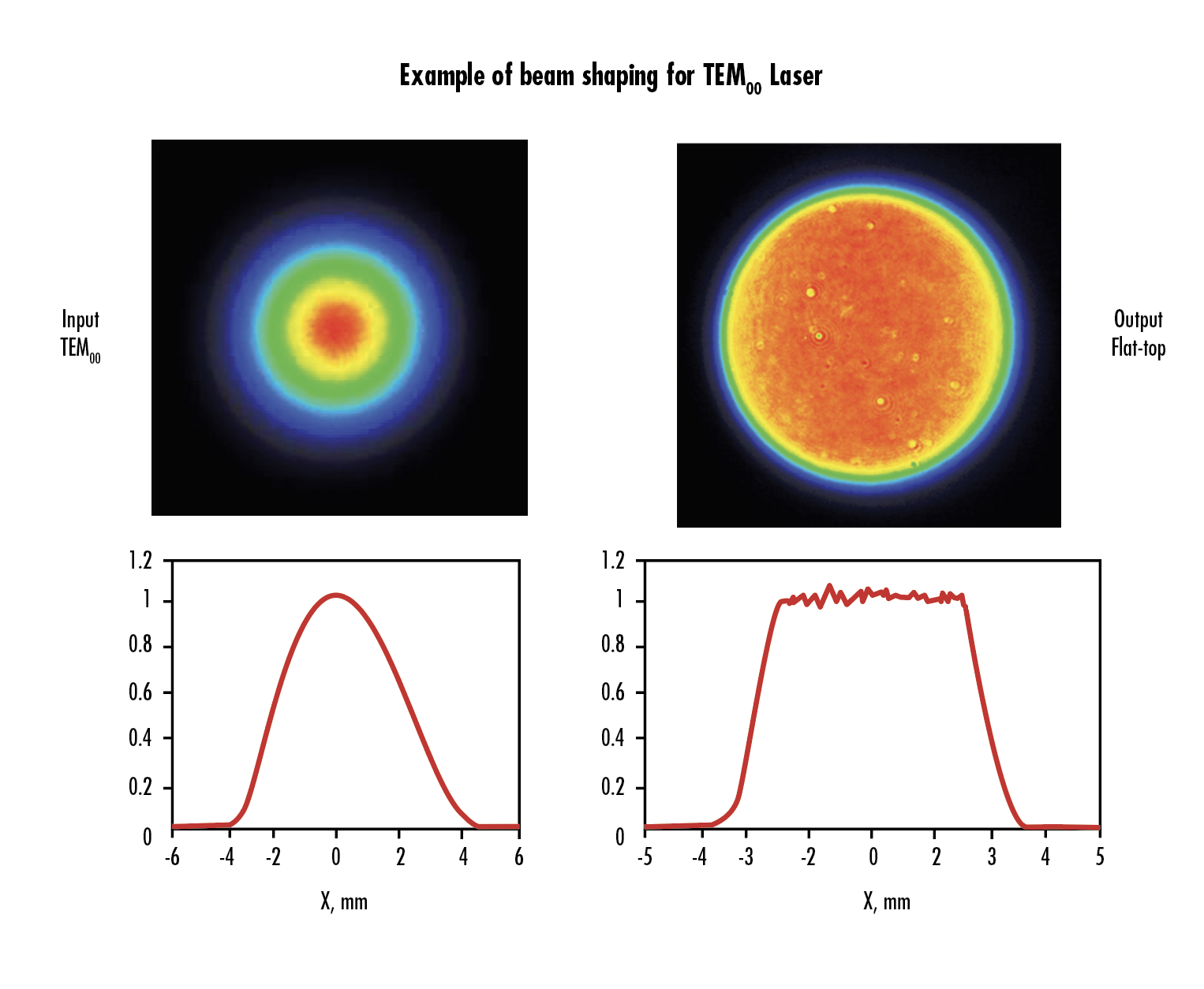

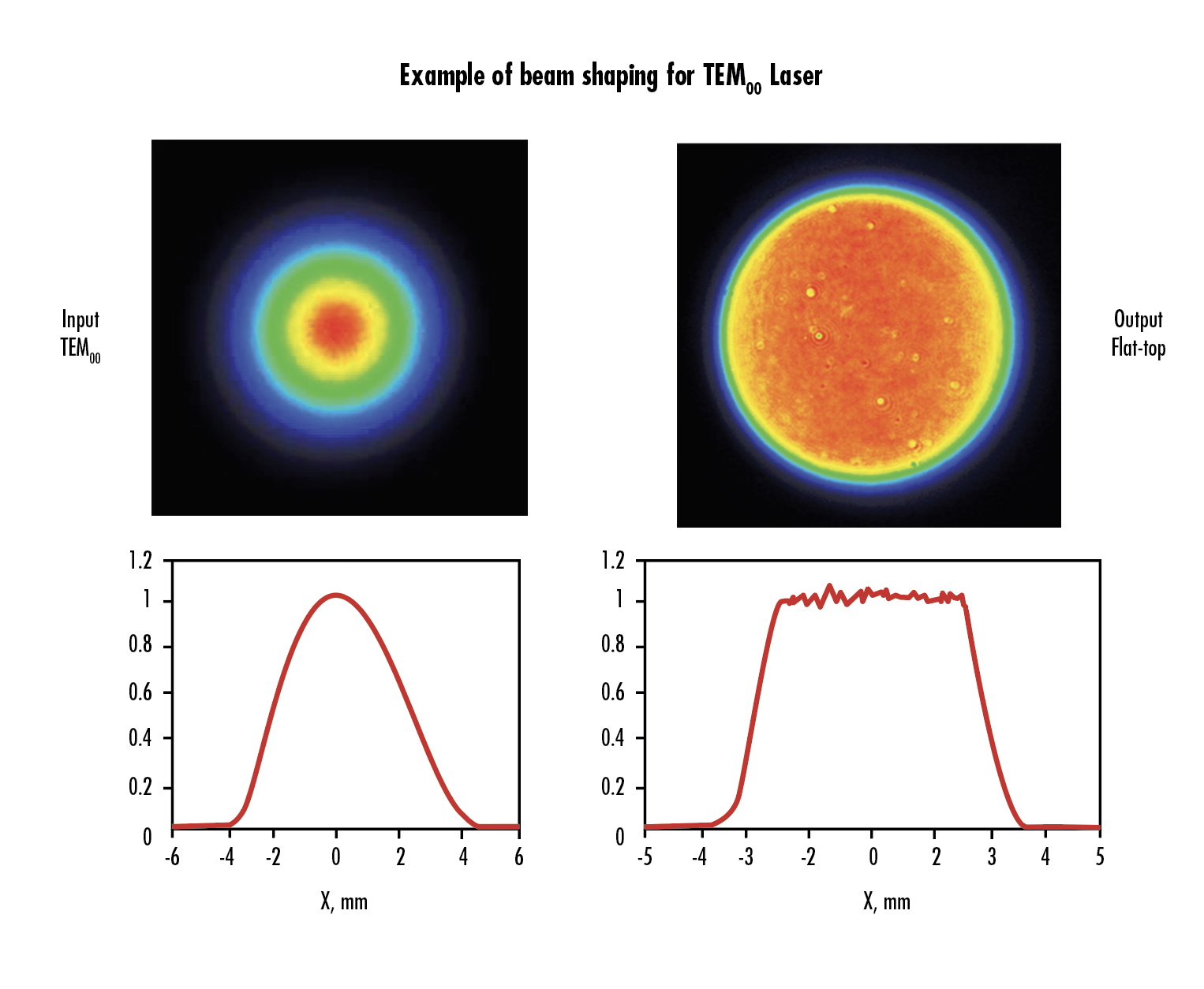

Flat top laser beams, as the name suggests, exhibit a unique characteristic— a flat, uniform intensity profile across the beam’s cross-section. Unlike Gaussian beams that have a bell-shaped intensity distribution, flat top beams maintain a constant intensity over a defined region. This feature holds immense importance in applications where a uniform energy distribution is required, such as laser material processing, microscopy, lithography, and laser-based 3D printing.

The traditional Gaussian beams exhibit a higher intensity at the center, gradually tapering off towards the edges. While they have been widely used in various fields, their intensity distribution can often lead to undesirable effects. For instance, in laser material processing, the non-uniform intensity profile of Gaussian beams may cause uneven material removal or thermal damage. The introduction of flat top laser beams addresses these challenges by providing a uniform intensity distribution, resulting in precise and consistent material processing.

Moreover, the unique beam shape of flat top laser beams offers additional advantages. Unlike Gaussian beams that have a single peak, flat top beams feature a flattened top surface. This shape enables efficient filling of rectangular or square areas, making them ideal for applications such as laser micromachining, surface texturing, and laser annealing of electronic components. The uniform intensity distribution combined with the rectangular beam shape enhances the overall process efficiency and quality.

In addition to their spatial properties, flat top laser beams also exhibit excellent beam quality. The well-defined beam profile allows for greater control over the laser’s focus and enables tighter focusing, resulting in higher precision and smaller spot sizes. This characteristic is particularly advantageous in applications like laser spectroscopy, optical trapping, and biomedical research, where fine control and high resolution are crucial.

In conclusion, flat top laser beams have emerged as a significant advancement in laser technology. Their uniform intensity distribution and unique beam shape offer a range of benefits in various applications, surpassing the limitations of traditional Gaussian beams. Whether it is precise material processing, efficient micromachining, or high-resolution imaging, flat top laser beams provide a new dimension in laser technology, unlocking new possibilities and pushing the boundaries of what lasers can achieve. With their increasing adoption across industries, flat top laser beams are paving the way for enhanced performance and improved outcomes in laser-based applications.

Techniques for Generating Flat Top Laser Beams

Laser beams with a uniform intensity distribution are desired in various applications, ranging from laser material processing to medical imaging. In this article, we will explore different methods used to generate flat top laser beams and how they can modify the beam profile to achieve a uniform intensity distribution.

One common technique used for beam shaping is the use of diffractive optical elements (DOEs). DOEs are optical components that utilize the principles of diffraction to shape laser beams. By employing carefully designed patterns, DOEs can alter the phase or amplitude of the incoming laser beam, resulting in a modified beam profile. In the case of generating a flat top beam, a DOE can be designed to introduce a phase shift that compensates for the inherent Gaussian profile of the laser beam, effectively transforming it into a flat top beam with a uniform intensity distribution.

Another approach to generating flat top laser beams is through the use of refractive optical systems. These systems employ lenses or lens arrays to manipulate the laser beam’s profile. By carefully selecting the shape and arrangement of the lenses, it is possible to shape the beam into a flat top distribution. The lenses can introduce controlled amounts of spherical aberration or other optical effects to modify the beam’s intensity profile. This method offers flexibility in adjusting the beam parameters and can be particularly useful when working with high-power lasers.

Digital holography is yet another technique that can be employed to generate flat top laser beams. Digital holography involves recording and reconstructing the interference pattern between a reference beam and the laser beam of interest. By applying suitable algorithms during the reconstruction process, the beam’s intensity profile can be modified to achieve a flat top distribution. Digital holography offers the advantage of great precision and flexibility, allowing for real-time adjustments of the beam profile.

It is worth noting that the choice of technique for generating flat top laser beams depends on various factors, including the required beam profile, power levels, and application-specific requirements. Each method has its own advantages and limitations, and the selection should be based on careful consideration of these factors.

In conclusion, generating flat top laser beams can be achieved through various techniques such as diffractive optical elements, refractive optical systems, and digital holography. These methods offer the means to modify the laser beam’s profile and achieve a uniform intensity distribution. The choice of technique depends on the specific requirements of the application at hand. With advancements in beam shaping technologies, the generation of flat top laser beams continues to play a vital role in a wide range of industries and scientific research.

Techniques for Generating Flat Top Laser Beams

Laser beams with a uniform intensity distribution are desired in various applications, ranging from laser material processing to medical imaging. In this article, we will explore different methods used to generate flat top laser beams and how they can modify the beam profile to achieve a uniform intensity distribution.

One common technique used for beam shaping is the use of diffractive optical elements (DOEs). DOEs are optical components that utilize the principles of diffraction to shape laser beams. By employing carefully designed patterns, DOEs can alter the phase or amplitude of the incoming laser beam, resulting in a modified beam profile. In the case of generating a flat top beam, a DOE can be designed to introduce a phase shift that compensates for the inherent Gaussian profile of the laser beam, effectively transforming it into a flat top beam with a uniform intensity distribution.

Another approach to generating flat top laser beams is through the use of refractive optical systems. These systems employ lenses or lens arrays to manipulate the laser beam’s profile. By carefully selecting the shape and arrangement of the lenses, it is possible to shape the beam into a flat top distribution. The lenses can introduce controlled amounts of spherical aberration or other optical effects to modify the beam’s intensity profile. This method offers flexibility in adjusting the beam parameters and can be particularly useful when working with high-power lasers.

Digital holography is yet another technique that can be employed to generate flat top laser beams. Digital holography involves recording and reconstructing the interference pattern between a reference beam and the laser beam of interest. By applying suitable algorithms during the reconstruction process, the beam’s intensity profile can be modified to achieve a flat top distribution. Digital holography offers the advantage of great precision and flexibility, allowing for real-time adjustments of the beam profile.

It is worth noting that the choice of technique for generating flat top laser beams depends on various factors, including the required beam profile, power levels, and application-specific requirements. Each method has its own advantages and limitations, and the selection should be based on careful consideration of these factors.

In conclusion, generating flat top laser beams can be achieved through various techniques such as diffractive optical elements, refractive optical systems, and digital holography. These methods offer the means to modify the laser beam’s profile and achieve a uniform intensity distribution. The choice of technique depends on the specific requirements of the application at hand. With advancements in beam shaping technologies, the generation of flat top laser beams continues to play a vital role in a wide range of industries and scientific research.

Flat top laser beams have revolutionized various fields of science and technology due to their unique characteristics. These laser beams possess a uniform intensity profile and controllable energy distribution, making them highly valuable in a wide range of applications. In this article, we will explore the diverse applications where flat top laser beams find utility and discuss how their precise and high-quality performance benefits various industries.

One of the significant fields where flat top laser beams have made a significant impact is laser micromachining. Laser micromachining involves the precise removal or alteration of materials on a microscale level. The uniform intensity profile of flat top laser beams ensures consistent material ablation or modification, resulting in highly accurate and controlled micromachining processes. Industries such as electronics, aerospace, and automotive rely on these laser beams for manufacturing intricate components and devices.

Another area where flat top laser beams excel is lithography. Lithography is a critical process used in the production of microchips and other integrated circuits. The uniform intensity profile of flat top laser beams enables precise exposure of photoresist materials, leading to high-resolution patterns on semiconductor substrates. This ensures the production of advanced and miniaturized electronic devices with improved performance and increased functionality.

Additive manufacturing, commonly known as 3D printing, has also benefited from the use of flat top laser beams. These laser beams play a crucial role in selective laser sintering and melting processes. By delivering a uniform intensity profile, flat top laser beams ensure consistent energy distribution across the build area, resulting in uniform melting or sintering of powdered materials. The use of flat top laser beams enhances the accuracy, surface finish, and structural integrity of 3D-printed components.

Laser annealing, a process that involves heating a material to alter its properties, is another field where flat top laser beams find utility. The uniform energy distribution of these laser beams allows for precise and controlled heating, minimizing the risk of overheating or damage to the material. Laser annealing is widely used in the semiconductor industry for dopant activation, improving crystal quality, and repairing defects on silicon wafers. Flat top laser beams ensure the reliability and quality of these annealing processes.

Furthermore, flat top laser beams have found applications in various medical procedures. Laser surgery, for example, benefits from the uniform intensity profile of these laser beams, enabling precise cutting, ablation, or coagulation of tissues. Ophthalmology, dermatology, and dentistry are among the medical specialties that utilize flat top laser beams for their accuracy and safety.

In conclusion, flat top laser beams have proven to be invaluable in a wide range of applications. From laser micromachining to lithography, additive manufacturing, laser annealing, and medical procedures, these laser beams enhance the precision and quality of processes in numerous industries. The uniform intensity profile and controllable energy distribution of flat top laser beams enable consistent and accurate results, making them an essential tool for advancing technology and scientific discoveries.

Future Prospects and Advancements in Flat Top Laser Beams

Flat top laser beams have emerged as a crucial tool in various scientific and industrial applications due to their unique beam profile. As technology continues to advance, ongoing research and development efforts are focused on further improving the quality, power levels, and flexibility of generating these beams. Additionally, exciting possibilities are arising in emerging fields like quantum computing and advanced optical communication systems. In this article, we will explore the future prospects and advancements in the field of flat top laser beams, including the latest research, technological breakthroughs, and potential applications.

Researchers and scientists are continuously exploring ways to enhance the beam quality of flat top lasers. Efforts are being made to reduce or eliminate undesirable properties, such as beam distortions or irregularities, to achieve a near-perfect flat top profile. Advanced optical components and precise beam shaping techniques are being developed to optimize laser systems for high-quality flat top beams. These advancements are crucial in applications where uniform intensity distribution is vital, such as laser material processing, lithography, or medical treatments.

Increasing the power levels of flat top laser beams is another area of interest for researchers. Higher power levels enable faster material processing and greater efficiency in various industrial applications. Advanced laser sources, including solid-state and fiber lasers, are being developed to generate high-power flat top beams. By combining these powerful lasers with sophisticated beam shaping technologies, researchers aim to provide industry with versatile tools that can handle demanding tasks efficiently.

Flexibility in generating flat top laser beams is also a significant focus of research. The ability to adjust the beam parameters, such as beam size, shape, and intensity distribution, according to specific application requirements is highly desirable. Researchers are exploring adaptive optics and dynamic beam shaping techniques to achieve real-time control over the beam profile. This flexibility opens up new possibilities for laser-based manufacturing, optical trapping, and holography, where tailored beam profiles are crucial for precise operations.

Moreover, the future of flat top laser beams extends beyond traditional applications. Exciting prospects lie in emerging fields such as quantum computing and advanced optical communication systems. Quantum computing, which relies on the manipulation of quantum states, requires precise control over laser beams for operations like qubit initialization and readout. Flat top laser beams with high beam quality and uniform intensity distribution could play a vital role in advancing the capabilities of quantum computing systems.

In the field of advanced optical communication systems, flat top laser beams offer advantages in terms of signal quality and transmission efficiency. These beams can help mitigate distortions caused by atmospheric turbulence or fiber optic imperfections, resulting in improved data transmission rates and reduced signal degradation. As the demand for high-speed, reliable data transfer continues to grow, flat top laser beams can contribute to enhancing the performance of optical communication networks.

In conclusion, the future of flat top laser beams looks promising, driven by ongoing research and advancements. With a focus on improving beam quality, increasing power levels, and enhancing flexibility, researchers are pushing the boundaries of laser technology. Furthermore, the potential applications in emerging fields like quantum computing and advanced optical communication systems offer exciting possibilities for the future. As technology continues to evolve, flat top laser beams are set to make a significant impact in various industries and pave the way for innovative advancements in science and technology.